Metal surfaces on firearms are often checkered, grooved, stippled or engine-turned to increase grip, reduce light reflection or simply for ornamental purposes.

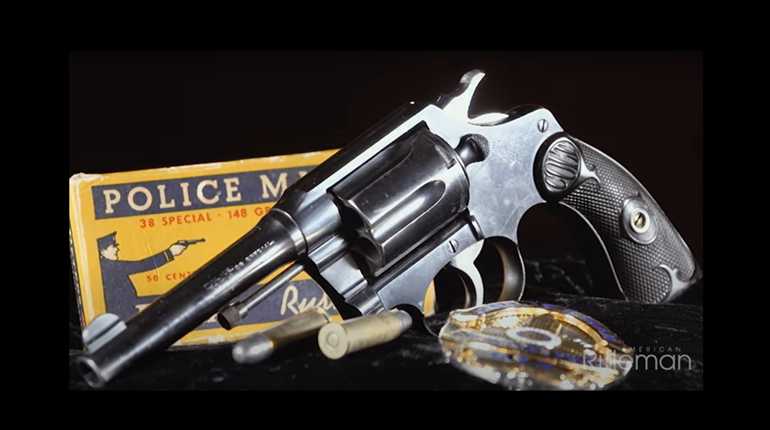

Checkering

Checkering consists of parallel grooves that intersect at an angle, producing small, sharp diamond-shaped projections. Checkering is frequently used on the front strap, back strap, trigger guard, operation levers and safety buttons of semi-auto handguns.

Metal checkering is produced with checkering files having two or more rows of parallel teeth. Checkering files are available with the rows of teeth spaced from 18, 20, 22, 24, 25, 30 and 40 lines per inch. Very fine checkering of 40 lines per inch or more is sometimes used on gun surfaces to break up light reflections, such as on the top of a handgun slide.

Grooving

Grooving is the production of a series of parallel cuts in the front strap and back strap, trigger bow or slide of a handgun to increase grip. Very fine grooes cut into the top of a pistol slide or solid rib or ventilated rib serve to reduce light reflection. Grooves are normally cut using checkering files. However, very coarse grooves may be cut on a machine or cast in the part.

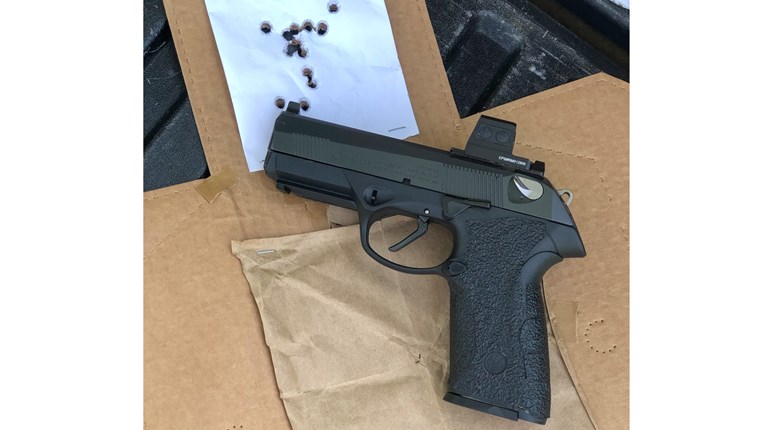

Stippling

Stippling is the creation of a rough surface texture formed by a series of shallow, random, overlapping punch marks. A sharp-pointed, hardened stippling punch is held at an angle to the surface and moved slightly as it is tapped repeatedly by a small hammer, creating the indentations. Stippling is normally used to enhance grip, but can also be used to reduce reflections on sighting surfaces.

Engine Turning

Typically used for decoration, engine turning is applied by a small abrasive-loaded rod that is held in a bit and rotated at moderate speed. When the abrasive rod is pressed against the metal surface, it leaves a shallow swirl. By overlapping the swirls, a decorative effect is produced. Typically, engine turning is applied to the magazine followers of bolt-action rifles.

Checkering

Checkering consists of parallel grooves that intersect at an angle, producing small, sharp diamond-shaped projections. Checkering is frequently used on the front strap, back strap, trigger guard, operation levers and safety buttons of semi-auto handguns.

Metal checkering is produced with checkering files having two or more rows of parallel teeth. Checkering files are available with the rows of teeth spaced from 18, 20, 22, 24, 25, 30 and 40 lines per inch. Very fine checkering of 40 lines per inch or more is sometimes used on gun surfaces to break up light reflections, such as on the top of a handgun slide.

Grooving

Grooving is the production of a series of parallel cuts in the front strap and back strap, trigger bow or slide of a handgun to increase grip. Very fine grooes cut into the top of a pistol slide or solid rib or ventilated rib serve to reduce light reflection. Grooves are normally cut using checkering files. However, very coarse grooves may be cut on a machine or cast in the part.

Stippling

Stippling is the creation of a rough surface texture formed by a series of shallow, random, overlapping punch marks. A sharp-pointed, hardened stippling punch is held at an angle to the surface and moved slightly as it is tapped repeatedly by a small hammer, creating the indentations. Stippling is normally used to enhance grip, but can also be used to reduce reflections on sighting surfaces.

Engine Turning

Typically used for decoration, engine turning is applied by a small abrasive-loaded rod that is held in a bit and rotated at moderate speed. When the abrasive rod is pressed against the metal surface, it leaves a shallow swirl. By overlapping the swirls, a decorative effect is produced. Typically, engine turning is applied to the magazine followers of bolt-action rifles.