Although many hunters and shooters prefer the aesthetics of a wooden stock, there are reasons why other people prefer synthetic stocks. For example, solid-wood gun stocks often suffer from dimensional instability when exposed to moisture, high humidity or changes in temperature. When this happens, the stock swells and warps, thereby significantly degrading accuracy and dramatically shifting the point of aim. Here's the skinny on the pros and cons (as well as the wherefores and hows).

Laminated Wood

Laminated wood stocks made from one or two types of wood cut into strips and glued together longitudinally can help ameliorate the problem of warping caused by ambient conditions. High-strength epoxy glue at high pressure impregnates the wood and ensures a good bond. For additional strength and stability, the grain of each wood layer is oriented at right angles to its neighbors. The thickness and type of laminates vary, though most commercial laminated stocks use layers of birch about one-sixteenth of an inch thick.

Because laminated stocks are considerably more stable than solid-wood stocks, they are a favorite choice for target or varmint rifles. For many shooters, the distinctive appearance of laminated stocks adds to their appeal. However, laminated-wood stocks are heavier and can be more expensive than solid-wood stocks of the same dimensions...and they can still warp if excess moisture is absorbed. Even when properly sealed, laminated-wood stocks are vulnerable to warping, swelling or other dimensional changes due to the absorption or release of moisture. Additionally, wood can deteriorate from exposure to solvents or gun oils; in fact, softening of the wood in the bedding area by repeated exposure to gun oil is a common problem. Wood can also crack as the result of accumulated stress from recoil, or from weakness at a critical point, such as the wrist. Consequently, stockmakers have long sought stronger alternatives to wood.

Fiberglass and Other Synthetics

In the 1970s, several companies began producing gunstocks made of fiberglass cloth. Fiberglass cloth is strong, dimensionally stable, resistant to solvents, and is unaffected by humidity, moisture or temperature variations. Additionally, it has shock-absorbing qualities that reduce the amount of perceived recoil. The original technique developed for making fiberglass stocks remains in use today. It involves hand-laying fiberglass layers in a mold, with epoxy resin to bind the layers into a solid shape. Next, the void inside the stock is filled with polyurethane foam and catalyst, which expands outward, pressing the layers of resin-impregnated fiberglass cloth tightly against the inside of the mold. When the bladder is deflated and removed, the space is filled with fiberglass beads or strands mixed with epoxy. Color can be added to the fiberglass layers during the molding process to lproduce an integral finish that will not chip, peel or crack and needs no maintenance. Alternatively, a gel coat about .04 inches thick can be applied to the finish stock. Such paint finishes can become showcases of art with complex designs, scenes and various colors.

Recently, other cloth materials have been used in conjunction with fiberglass, such as Kevlar and carbon fiber. In most cases, such materials are used to supplement fiberglass cloth rather than replacing it—for example, in high stress areas such as the wrist and fore-end. One such example, Dupont's Kevlar para-aramid fiber, renowned for its use in bulletproof vests, is five times stronger than steel on an equal-weight basis. However, it is substantially more expensive than fiberglass cloth, insufficiently rigid to be used as teh sole material in a long gun stock, and is harder to lay up in a mold. Carbon or graphite fiber cloths offer light weight with a high stiffness-to-weight ratio, making them useful on stocks that must be ultra-light but rigid, such as benchrest and other competition stocks. However, carbon or graphite fibers are extremely expensive and their directional strength often requires complex lay-up patterns.

Synthetic stocks of injection-molded plastics such as nylon have been used successfully for gunstocks since the early 1960s. This type of inexpensive, light and stable gunstock is suitable for rimfire rifles and airguns, but lacks the strength necessary for centerfire rifles or shotguns.

In recent years, reaction molding technology has matured using new resins, new molding processes and fiberglass filling materials. These advances allow a significant increase in the strength of molded gunstocks such that they are sufficiently strong for use in centerfire rifles and shotguns. Though they are less rigid than laid-up fiberglass stocks, molded gunstocks are inexpensive, weather-resistant, require little to no maintenance and can withstand considerable punishment. They can also be molded into shapes difficult or impossible to create in wood, and the color or camouflage pattern can be molded into the stock material itself.

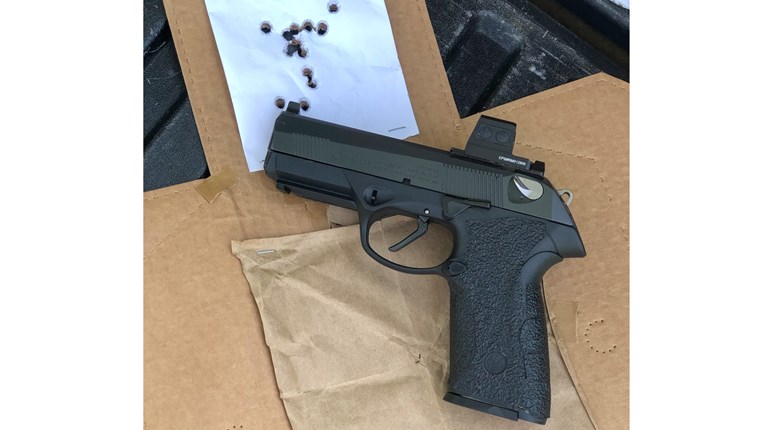

Synthetic materials for handgun stocks include a variety of molded plastics of various colors, as well as laminates such as Micarta, a high-pressure laminate of layers of linen cloth and resinous binders. Also popular are various soft-rubber units of one- or two-piece construction. Rubber grips absorb recoil as well as provide a more secure gripping surface. This makes for a more enjoyable range experience, but might not be suited for concealed carry as their non-slip surfaces tend to cling to clothing and reveal the presence of a gun.